qid

int64 4

8.14M

| question

stringlengths 20

48.3k

| answers

list | date

stringlengths 10

10

| metadata

sequence | input

stringlengths 12

45k

| output

stringlengths 2

31.8k

|

|---|---|---|---|---|---|---|

6,377 | <p>I'm printing parts for a HEVO (<a href="https://www.thingiverse.com/thing:2254103" rel="nofollow noreferrer">HyperCube Evolution</a> CoreXY), using Colorfabb XT filament. After several successful prints. I'm having a lot of failed prints. They start off pretty well but after ~15 layers the filament starts to string and blob. </p>

<p>Printer details</p>

<pre><code>Model: RepRap i3

Extruder: E3D 1.75 all metal hotend.

Nozzle: .4

Print temp: 260°C (max. recommended).

</code></pre>

<p>Steps I took to troubleshoot</p>

<ol>

<li>First I thought my nozzle was clogged. But it's not I can push the filament by hand without issues.</li>

<li>Lowered the speed to 35 mm/s.</li>

<li>Disabled retraction / disabled part cooling.</li>

<li>increased the max temp with 10 % to ensure the filament flow</li>

</ol>

<p>Printed parts that fail: </p>

<p><a href="https://i.stack.imgur.com/2wEjO.jpg" rel="nofollow noreferrer" title="Top view printed part"><img src="https://i.stack.imgur.com/2wEjO.jpg" alt="Top view printed part" title="Top view printed part"></a>

<em>Note: the two parts on the left are printed in one job</em></p>

<p><a href="https://i.stack.imgur.com/1jure.jpg" rel="nofollow noreferrer" title="Side view printed part"><img src="https://i.stack.imgur.com/1jure.jpg" alt="Side view printed part" title="Side view printed part"></a></p>

<p>UPDATE 26/07

Dit a few more prints with PETG to eliminate the moisture problem. Same results.</p>

<p><a href="https://i.stack.imgur.com/l6vj4.jpg" rel="nofollow noreferrer"><img src="https://i.stack.imgur.com/l6vj4.jpg" alt="PETG"></a></p>

<p><a href="https://i.stack.imgur.com/GL1IF.jpg" rel="nofollow noreferrer"><img src="https://i.stack.imgur.com/GL1IF.jpg" alt="PETG2"></a></p>

| [

{

"answer_id": 6390,

"author": "Valmond",

"author_id": 8328,

"author_profile": "https://3dprinting.stackexchange.com/users/8328",

"pm_score": 3,

"selected": false,

"text": "<p>This looks a lot like <strong>under extrusion caused by heat creep</strong>.</p>\n\n<p>Heat creep is when the nozzle temperature 'creeps' up through the filament and makes it melt (a bit) and form a blob (or just widen enough to get stuck) a centimeter or two before the nozzle.</p>\n\n<p>The characteristic is usually that everything works perfectly well for some quite fix amount of time, then there is severe under extrusion.</p>\n\n<p>Solutions:</p>\n\n<ul>\n<li>Lower the temperature (yes, as then the heat won't creep as much!)</li>\n<li>Add a fan cooling down the cooling part of the print head</li>\n</ul>\n\n<p>I have the same print head as you it seems (E3D 1.75 all metal) and I had heat creep when I changed the fan to a less noisy one (but also less effective).</p>\n"

},

{

"answer_id": 6393,

"author": "Sean Houlihane",

"author_id": 4927,

"author_profile": "https://3dprinting.stackexchange.com/users/4927",

"pm_score": 3,

"selected": false,

"text": "<p>This suggestion may not apply in your specific case (you seem to have looked closely at the problem, and it doesn't really fit the apparent time-dependence) but you might have an issue with the extrusion drive. If your hobbed drive isn't tight on the stepper motor then the 'push' might not be enough to match the force you've tested by hand. This explains one way that the extruder can be more sensitive to small performance variations than you would normally expect (heat build up somehow contributing to those variations).</p>\n"

},

{

"answer_id": 6408,

"author": "Toon",

"author_id": 9303,

"author_profile": "https://3dprinting.stackexchange.com/users/9303",

"pm_score": 2,

"selected": false,

"text": "<p>I have a possible cause for my problems. XT is sensitive to moisture (hydrolytical stability) When I extruded 20mm filament manually, the string felt a bit rough. When I looked closer very tiny bubbels where visible. I baked the filament at 60°C for 2 hours.</p>\n\n<p>The baked filament allowed me to print a perfect model. </p>\n\n<p>But after one print the filament is again affected by moisture so I need to build a dry-box and do some more tests before I come to a conclusion. </p>\n"

}

] | 2018/07/11 | [

"https://3dprinting.stackexchange.com/questions/6377",

"https://3dprinting.stackexchange.com",

"https://3dprinting.stackexchange.com/users/9303/"

] | I'm printing parts for a HEVO ([HyperCube Evolution](https://www.thingiverse.com/thing:2254103) CoreXY), using Colorfabb XT filament. After several successful prints. I'm having a lot of failed prints. They start off pretty well but after ~15 layers the filament starts to string and blob.

Printer details

```

Model: RepRap i3

Extruder: E3D 1.75 all metal hotend.

Nozzle: .4

Print temp: 260°C (max. recommended).

```

Steps I took to troubleshoot

1. First I thought my nozzle was clogged. But it's not I can push the filament by hand without issues.

2. Lowered the speed to 35 mm/s.

3. Disabled retraction / disabled part cooling.

4. increased the max temp with 10 % to ensure the filament flow

Printed parts that fail:

[](https://i.stack.imgur.com/2wEjO.jpg "Top view printed part")

*Note: the two parts on the left are printed in one job*

[](https://i.stack.imgur.com/1jure.jpg "Side view printed part")

UPDATE 26/07

Dit a few more prints with PETG to eliminate the moisture problem. Same results.

[](https://i.stack.imgur.com/l6vj4.jpg)

[](https://i.stack.imgur.com/GL1IF.jpg) | This looks a lot like **under extrusion caused by heat creep**.

Heat creep is when the nozzle temperature 'creeps' up through the filament and makes it melt (a bit) and form a blob (or just widen enough to get stuck) a centimeter or two before the nozzle.

The characteristic is usually that everything works perfectly well for some quite fix amount of time, then there is severe under extrusion.

Solutions:

* Lower the temperature (yes, as then the heat won't creep as much!)

* Add a fan cooling down the cooling part of the print head

I have the same print head as you it seems (E3D 1.75 all metal) and I had heat creep when I changed the fan to a less noisy one (but also less effective). |

6,399 | <p>I got myself the Ender 3. The Home position is about 1 mm left and 2 mm in front of the front left corner. Now, the hotend center axis is 11 mm from the carrier plate with the "Mk 10" cooler mounted right onto a pair of 5 mm pegs that are part of the plate. As I want to change to an e3D v6, which has a diameter of 22 mm, I will have to move out some distance (ca. 13 mm) to the current Z axis. This means, that any Y command will be off by this distance.</p>

<p><strong>How do I reconfigure the Home position to have an offset to the 0-positions gained from the limit switches?</strong></p>

<p>According to Repetier Host it runs on <strong>Marlin 1.0</strong>. Creality offers the firmware on <a href="https://www.creality3d.cn/download/firmware_c0001" rel="nofollow noreferrer">their website</a> as a <strong>.hex</strong> file - which is hard to edit.</p>

| [

{

"answer_id": 6405,

"author": "0scar",

"author_id": 5740,

"author_profile": "https://3dprinting.stackexchange.com/users/5740",

"pm_score": 3,

"selected": false,

"text": "<p>When homing the printer, the hot end carriage will be instructed to hit the (mechanical or optical) end stops. From this point a well configured firmware knows where to find the origin of the heat bed. </p>\n\n<p>For the printer to know the origin of the bed, offsets are defined in the firmware from the end stop locations to the actual origin of the heat bed. </p>\n\n<p>E.g. in Marlin Firmware this is defined by</p>\n\n<pre><code> #define X_MIN_POS -35 ; move the head 35 mm to the right to place the \n ; nozzle at X = 0\n #define Y_MIN_POS -8 ; move the head 8 mm to the back (or the plate\n ; forward) to place the nozzle at Y = 0\n</code></pre>\n\n<p>When you change the hardware (e.g. carriage), you need to re-calibrate the movement from the end stop location to the origin of the bed. Note that any arbitrary point on the heat bed can be used to re-calibrate this. E.g. the center of the bed can also be used, and is frequently much more easy to re-calibrate as the heated beds usually have rounded corners or are slightly larger than the actual print area (e.g. I have a 300 x 300 mm heat bed that actually measures 315 x 315 mm). Printing a large square on the heat bed will therefore give you a good impression of the offset of the nozzle due to your new carriage design. </p>\n\n<p>Note that, if you cannot or will not flash new firmware, an alternative solution exists to set new incremental offset values using the <a href=\"https://reprap.org/wiki/G-code#M206:_Offset_axes\" rel=\"noreferrer\"><code>M206</code></a> command <strong>IF</strong> <a href=\"https://reprap.org/wiki/G-code#M206:_Offset_axes\" rel=\"noreferrer\">your current firmware supports</a> this.</p>\n\n<p>A detailed description to re-calibrate is found in answer <a href=\"https://3dprinting.stackexchange.com/a/6376/5740\">How to center my prints on the build platform?</a> or in external link <a href=\"https://www.thingiverse.com/thing:2280529\" rel=\"noreferrer\">Bed center calibration</a>.</p>\n"

},

{

"answer_id": 6648,

"author": "Greenonline",

"author_id": 4762,

"author_profile": "https://3dprinting.stackexchange.com/users/4762",

"pm_score": 2,

"selected": false,

"text": "<p><em>Following on from 0scar's answer</em></p>\n<hr />\n<p>To change or obtain your EEPROM settings you need to open Repetier Host (for Linux or Windows, v2.1.3 - the OSX version I tried, v1.1.0, didn't seem to have this functionality).</p>\n<h3>To change existing settings</h3>\n<p>From <a href=\"https://forum.repetier.com/discussion/4641/how-to-make-changes-to-the-eeprom-data\" rel=\"nofollow noreferrer\">How to make changes to the EEPROM data</a>. Apparently there is an EEPROM editor available (in Repetier Host). From <a href=\"https://forum.repetier.com/discussion/comment/18712/#Comment_18712\" rel=\"nofollow noreferrer\">this post</a>:</p>\n<blockquote>\n<p>If you see it in eeprom editor just change them. If it is repetier-firmware based it will store changes in eeprom on pressing "ok".</p>\n</blockquote>\n<h3>To retrieve existing settings</h3>\n<p><a href=\"https://forum.repetier.com/discussion/comment/2817/#Comment_2817\" rel=\"nofollow noreferrer\">This post</a> from <a href=\"https://forum.repetier.com/discussion/933/retrieval-of-existing-settings\" rel=\"nofollow noreferrer\">retrieval of existing settings...</a>, shows how:</p>\n<blockquote>\n<p>To copy eeprom data:</p>\n<ul>\n<li>Connect with host</li>\n<li>Open eeprom settings</li>\n<li>Select export eeprom settings. That saves all data in a epr file and you can later use import eepsom settings to rewrite it.</li>\n</ul>\n</blockquote>\n<p>An example of the resulting file is shown in the question, <a href=\"https://3dprinting.stackexchange.com/questions/4184/help-with-repetier-firmware-variables-dimension-dual-delta-j-group-robotics\">Help with Repetier firmware variables (Dimension Dual Delta - J Group Robotics)</a>, a sample of which I have included below:</p>\n<pre><code><Repetier-Firmware-EEPROM>\n<epr pos="1028" type="0" value="0">Language</epr>\n<epr pos="75" type="2" value="115200">Baudrate</epr>\n<epr pos="129" type="3" value="32.752">Filament printed [m]</epr>\n<epr pos="125" type="2" value="21644">Printer active [s]</epr>\n<epr pos="79" type="2" value="0">Max. inactive time [ms,0=off]</epr>\n</code></pre>\n<hr />\n<p>However, you would appear to have to be running Repetier firmware for these two solutions to work, and not Marlin (but I may be wrong).</p>\n"

},

{

"answer_id": 6660,

"author": "Trish",

"author_id": 8884,

"author_profile": "https://3dprinting.stackexchange.com/users/8884",

"pm_score": 3,

"selected": true,

"text": "<p><a href=\"https://3dprinting.stackexchange.com/users/4762/greenonline\">Greenonline</a> and I spent this evening hacking/reverse engineering the Ender3 to solve this. <a href=\"https://gr33nonline.wordpress.com/2018/08/13/compiling-marlin-for-a-creality-ender-3/\" rel=\"nofollow noreferrer\">Greenonline also wrote about this in his blog</a>.</p>\n<h2>Step 1 - Get the Firmware</h2>\n<p>To do this, there are basically two ways:</p>\n<ol>\n<li>Find the a ready-to-use firmware</li>\n<li>Make your own</li>\n</ol>\n<p>Variant 1 would be to use the pre-supplied .hex files from Creality or some other manufacturer. Variant 2 means writing the settings yourself or using <a href=\"https://www.repetier.com/firmware/v100/\" rel=\"nofollow noreferrer\">Repetier firmware</a> to write the files for you. In the case of the Ender 3, the chip used sadly disqualified Repetier firmware, so writing it yourself is the only option.</p>\n<p>To write the firmware yourself or using Repetier firmware, you need the old settings. To get these, connect the printer via USB, connect it with a software like <a href=\"https://www.repetier.com/\" rel=\"nofollow noreferrer\">Repetier host</a> and send <a href=\"http://marlinfw.org/docs/gcode/M503.html\" rel=\"nofollow noreferrer\"><code>M503</code></a> to get all the settings.</p>\n<p>Now, either hack those into Repetier firmware or use a blank <a href=\"http://marlinfw.org/meta/download/\" rel=\"nofollow noreferrer\"><code>Marlin.ino</code></a> and the Arduino IDE to customise it. In the later case, you need to put the folder <code>Marlin-?.?.X.ZIP/Marlin-?.?.X/Marlin</code> into the <code>Arduino</code> folder in Documents (Windows) or Home (Mac). Now open the <code>Marlin.ino</code> in <a href=\"https://www.arduino.cc/en/Main/Software\" rel=\"nofollow noreferrer\">Arduino IDE</a>. Set up the new firmware with these base settings or adjust as needed.</p>\n<h2>Step 2 - Adjust</h2>\n<p>Now that we have our Configuration files (in the end we pretty much skipped step 1 and <a href=\"https://www.chaos-drucker.de/wp-content/uploads/2018/04/Marlin-Ender3-V1.zip\" rel=\"nofollow noreferrer\">grabbed a fitting (<strong>German!</strong>) one</a> from <a href=\"https://www.chaos-drucker.de/anleitungen-und-tutorials/creality-ender3-mit-marlin-ausstatten/\" rel=\"nofollow noreferrer\">Christian</a>, a German maker also known as "Chaos-Drucker"), we need to first adjust them as needed to fit our needs and then compile them properly (next step!). As an alternative (<strong>English!</strong>) base to work with, the <a href=\"https://www.th3dstudio.com/knowledge-base/th3d-unified-firmware/?seq_no=10\" rel=\"nofollow noreferrer\">TH3D firmware</a> is also available, provided by the Hooglands and team at TH3D.</p>\n<p>So, let's open your <code>Marlin.ino</code> with <a href=\"https://www.arduino.cc/en/Main/Software\" rel=\"nofollow noreferrer\">arduino</a> and find the <code>X_MIN_POS</code> (<code>CTRL</code>+<code>F</code> > <code>X_MIN_POS</code> > Search all sketches).</p>\n<p>In the configurations we grabbed the sketch file <code>Configuration.h</code> contains lines 786-789 <em>(might differ)</em>:</p>\n<pre><code>// Travel limits (mm) after homing, corresponding to endstop positions.\n#define X_MIN_POS -10\n#define Y_MIN_POS -15\n#define Z_MIN_POS 0\n</code></pre>\n<p>Adjust these till the wanted position is achieved - Repetier Host can help here to determine the right position.</p>\n<h2>Step 3 - Compile</h2>\n<p>The hardest step with the Ender3 was to get the code to actually compile, as it uses an <a href=\"http://www.technoblogy.com/show?19OV\" rel=\"nofollow noreferrer\">ATmega1284P 16Bit</a> which isn't supported by Arduino natively. While the <a href=\"https://github.com/MCUdude/MightyCore\" rel=\"nofollow noreferrer\">MightyCore</a> supports this chip, it doesn't compile with this hardware library. However, Christian did figure out that the <a href=\"https://github.com/Lauszus/Sanguino\" rel=\"nofollow noreferrer\">Sanguino</a> set to an ATmega 1284P 16bit does work. These belong as <em>extracted folders</em> into the <code>Arduino/hardware</code> folder, usually in your Documents (if you use Windows) or Home (on mac). Now, we did set <code>Tools>Board:> Sanguino</code> and <code>Tools>Processor:>ATmega1284 or ATmega1284P (16 MHz)</code></p>\n<p>It was also mandatory to have the <a href=\"https://github.com/olikraus/U8glib_Arduino\" rel=\"nofollow noreferrer\">U8glib.h for Arduino</a> installed. To do this, download the zip from github, then in the Arduino software <code>Sketch>Include Library>Add .ZIP Library...</code> and choose the whole zip repository to auto install.</p>\n<p>With these settings we were able to compile the settings.</p>\n<h2>Step 4 - Getting it on the machine</h2>\n<p>Most people would expect to read about bootloaders and flashing now, and indeed that is an option. But as I had just figured out <a href=\"https://3dprinting.stackexchange.com/questions/6654/how-to-install-a-hex-firmware\">how to install firmware from .hex</a> and so I wondered: Can't we make .hex files from our settings? And yes, <a href=\"https://3dprinting.stackexchange.com/a/6658/8884\">Arduino supports this</a>.</p>\n<p>So, in Arduino IDE press <code>Ctrl</code>+<code>Alt</code>+<code>S</code> (or <code>Sketch > Export Compiled Binary</code>). This will result in two files:</p>\n<ul>\n<li><code>Marlin.ino.sanguino.hex</code></li>\n<li><code>Marlin.ino.with_bootloader.sanguino.hex</code></li>\n</ul>\n<p>Of these two, the <code>Marlin.ino.sanguino.hex</code> is the interesting one for "direct flashing" via CURA. Use this file with the process starting at Step 2 <a href=\"https://3dprinting.stackexchange.com/a/6655/8884\">here</a> or use one of <a href=\"https://3dprinting.stackexchange.com/a/6656/8884\">Greenonline's solutions</a> to get the firmware flashed - no bootloader needed!</p>\n"

}

] | 2018/07/14 | [

"https://3dprinting.stackexchange.com/questions/6399",

"https://3dprinting.stackexchange.com",

"https://3dprinting.stackexchange.com/users/8884/"

] | I got myself the Ender 3. The Home position is about 1 mm left and 2 mm in front of the front left corner. Now, the hotend center axis is 11 mm from the carrier plate with the "Mk 10" cooler mounted right onto a pair of 5 mm pegs that are part of the plate. As I want to change to an e3D v6, which has a diameter of 22 mm, I will have to move out some distance (ca. 13 mm) to the current Z axis. This means, that any Y command will be off by this distance.

**How do I reconfigure the Home position to have an offset to the 0-positions gained from the limit switches?**

According to Repetier Host it runs on **Marlin 1.0**. Creality offers the firmware on [their website](https://www.creality3d.cn/download/firmware_c0001) as a **.hex** file - which is hard to edit. | [Greenonline](https://3dprinting.stackexchange.com/users/4762/greenonline) and I spent this evening hacking/reverse engineering the Ender3 to solve this. [Greenonline also wrote about this in his blog](https://gr33nonline.wordpress.com/2018/08/13/compiling-marlin-for-a-creality-ender-3/).

Step 1 - Get the Firmware

-------------------------

To do this, there are basically two ways:

1. Find the a ready-to-use firmware

2. Make your own

Variant 1 would be to use the pre-supplied .hex files from Creality or some other manufacturer. Variant 2 means writing the settings yourself or using [Repetier firmware](https://www.repetier.com/firmware/v100/) to write the files for you. In the case of the Ender 3, the chip used sadly disqualified Repetier firmware, so writing it yourself is the only option.

To write the firmware yourself or using Repetier firmware, you need the old settings. To get these, connect the printer via USB, connect it with a software like [Repetier host](https://www.repetier.com/) and send [`M503`](http://marlinfw.org/docs/gcode/M503.html) to get all the settings.

Now, either hack those into Repetier firmware or use a blank [`Marlin.ino`](http://marlinfw.org/meta/download/) and the Arduino IDE to customise it. In the later case, you need to put the folder `Marlin-?.?.X.ZIP/Marlin-?.?.X/Marlin` into the `Arduino` folder in Documents (Windows) or Home (Mac). Now open the `Marlin.ino` in [Arduino IDE](https://www.arduino.cc/en/Main/Software). Set up the new firmware with these base settings or adjust as needed.

Step 2 - Adjust

---------------

Now that we have our Configuration files (in the end we pretty much skipped step 1 and [grabbed a fitting (**German!**) one](https://www.chaos-drucker.de/wp-content/uploads/2018/04/Marlin-Ender3-V1.zip) from [Christian](https://www.chaos-drucker.de/anleitungen-und-tutorials/creality-ender3-mit-marlin-ausstatten/), a German maker also known as "Chaos-Drucker"), we need to first adjust them as needed to fit our needs and then compile them properly (next step!). As an alternative (**English!**) base to work with, the [TH3D firmware](https://www.th3dstudio.com/knowledge-base/th3d-unified-firmware/?seq_no=10) is also available, provided by the Hooglands and team at TH3D.

So, let's open your `Marlin.ino` with [arduino](https://www.arduino.cc/en/Main/Software) and find the `X_MIN_POS` (`CTRL`+`F` > `X_MIN_POS` > Search all sketches).

In the configurations we grabbed the sketch file `Configuration.h` contains lines 786-789 *(might differ)*:

```

// Travel limits (mm) after homing, corresponding to endstop positions.

#define X_MIN_POS -10

#define Y_MIN_POS -15

#define Z_MIN_POS 0

```

Adjust these till the wanted position is achieved - Repetier Host can help here to determine the right position.

Step 3 - Compile

----------------

The hardest step with the Ender3 was to get the code to actually compile, as it uses an [ATmega1284P 16Bit](http://www.technoblogy.com/show?19OV) which isn't supported by Arduino natively. While the [MightyCore](https://github.com/MCUdude/MightyCore) supports this chip, it doesn't compile with this hardware library. However, Christian did figure out that the [Sanguino](https://github.com/Lauszus/Sanguino) set to an ATmega 1284P 16bit does work. These belong as *extracted folders* into the `Arduino/hardware` folder, usually in your Documents (if you use Windows) or Home (on mac). Now, we did set `Tools>Board:> Sanguino` and `Tools>Processor:>ATmega1284 or ATmega1284P (16 MHz)`

It was also mandatory to have the [U8glib.h for Arduino](https://github.com/olikraus/U8glib_Arduino) installed. To do this, download the zip from github, then in the Arduino software `Sketch>Include Library>Add .ZIP Library...` and choose the whole zip repository to auto install.

With these settings we were able to compile the settings.

Step 4 - Getting it on the machine

----------------------------------

Most people would expect to read about bootloaders and flashing now, and indeed that is an option. But as I had just figured out [how to install firmware from .hex](https://3dprinting.stackexchange.com/questions/6654/how-to-install-a-hex-firmware) and so I wondered: Can't we make .hex files from our settings? And yes, [Arduino supports this](https://3dprinting.stackexchange.com/a/6658/8884).

So, in Arduino IDE press `Ctrl`+`Alt`+`S` (or `Sketch > Export Compiled Binary`). This will result in two files:

* `Marlin.ino.sanguino.hex`

* `Marlin.ino.with_bootloader.sanguino.hex`

Of these two, the `Marlin.ino.sanguino.hex` is the interesting one for "direct flashing" via CURA. Use this file with the process starting at Step 2 [here](https://3dprinting.stackexchange.com/a/6655/8884) or use one of [Greenonline's solutions](https://3dprinting.stackexchange.com/a/6656/8884) to get the firmware flashed - no bootloader needed! |

6,410 | <p>I am wondering if this piece of G-code is valid:</p>

<pre><code>G0 (Some comment (Its G0 command)) Y10 Z-5

</code></pre>

<p>I have tested this on my Chinese CNC machine and it strips out the comment and works flawlessly.</p>

<p>The machine processes this as <code>G0Y10Z-5</code> which seems like the correct approach to me.</p>

<p>I have however never seen such comment in real CNC practise.

It would be nice if anyone is able to test it out on their CNC/3D Printer.</p>

<p>Many G-code simulators on the internet fail to process such a line in their parser so it makes me confused. I haven't found anything about it on RepRap Wiki or even Google.</p>

| [

{

"answer_id": 6411,

"author": "Tom van der Zanden",

"author_id": 26,

"author_profile": "https://3dprinting.stackexchange.com/users/26",

"pm_score": 4,

"selected": false,

"text": "<p>This is not universally valid G-code, and how it is handled depends on the implementation. You can use this style of comment on <em>some</em> machines, but not all.</p>\n\n<p>The way parsing used to be implemented in Marlin (a very common 3D printer firmware), it would work fine unless the comment string included a X, Y, Z, E or F character. The parser simply looks for the first occurrence of X/Y/Z/E/F and then tries to parse the bit of text appearing after that character into a number. If the string cannot be parsed as a number, it defaults to 0 instead. For example,</p>\n\n<pre><code> G0 (Some comment containing the character Y) Y10 Z-5\n</code></pre>\n\n<p>would be interpreted as <code>G0 Y0 Z-5</code> and not as <code>G0 Y10 Z-5</code>, because \") \" (the string appearing after the first occurrence of \"Y\") does not parse to any valid number. Your example happens to work fine because the comment string doesn't contain any special characters.</p>\n\n<p>Marlin does support end-of-line comments, which should start with a semicolon and continue until the end of the line.</p>\n\n<p>This is how it used to work in older Marlin versions. Newer Marlin versions have a more advanced parser, but it still would not play well with these parentheses-style comments. It is best to avoid them, as compatibility is not guaranteed.</p>\n"

},

{

"answer_id": 6412,

"author": "Jan Vorisek",

"author_id": 12353,

"author_profile": "https://3dprinting.stackexchange.com/users/12353",

"pm_score": 3,

"selected": true,

"text": "<p>It looks like comments inside parentheses are not allowed in numerous parsers (ie. Marlin). This seems to be true for most of the 3D printers. Classical CNC milling machines use parentheses without problems.</p>\n<p>It should work on Prusa printers as stated in their <a href=\"https://reprap.org/wiki/G-code#Comments\" rel=\"nofollow noreferrer\">Wiki</a>. Unfortunately there are no words about nesting of the comments.</p>\n<p>I have however found a comment on cnczone.com forums regarding the nesting of comments within parentheses.</p>\n<blockquote>\n<p>Printable characters and white space inside parentheses is a comment. A left parenthesis always starts a comment. The comment ends at the first right parenthesis found thereafter.</p>\n<p>Once a left parenthesis is placed on a line, a matching right parenthesis must appear before the end of the line.</p>\n<p>Comments may not be nested; it is an error if a left parenthesis is found after the start of a comment and before the end of the comment.</p>\n<p>Here is an example of a line containing a comment: <code>G80 M5 (stop motion)</code></p>\n</blockquote>\n<p>Source: <a href=\"https://www.cnczone.com/forums/g-code-programing/103434-coments-g-code.html#post763510\" rel=\"nofollow noreferrer\">cnczone.com</a></p>\n"

}

] | 2018/07/16 | [

"https://3dprinting.stackexchange.com/questions/6410",

"https://3dprinting.stackexchange.com",

"https://3dprinting.stackexchange.com/users/12353/"

] | I am wondering if this piece of G-code is valid:

```

G0 (Some comment (Its G0 command)) Y10 Z-5

```

I have tested this on my Chinese CNC machine and it strips out the comment and works flawlessly.

The machine processes this as `G0Y10Z-5` which seems like the correct approach to me.

I have however never seen such comment in real CNC practise.

It would be nice if anyone is able to test it out on their CNC/3D Printer.

Many G-code simulators on the internet fail to process such a line in their parser so it makes me confused. I haven't found anything about it on RepRap Wiki or even Google. | It looks like comments inside parentheses are not allowed in numerous parsers (ie. Marlin). This seems to be true for most of the 3D printers. Classical CNC milling machines use parentheses without problems.

It should work on Prusa printers as stated in their [Wiki](https://reprap.org/wiki/G-code#Comments). Unfortunately there are no words about nesting of the comments.

I have however found a comment on cnczone.com forums regarding the nesting of comments within parentheses.

>

> Printable characters and white space inside parentheses is a comment. A left parenthesis always starts a comment. The comment ends at the first right parenthesis found thereafter.

>

>

> Once a left parenthesis is placed on a line, a matching right parenthesis must appear before the end of the line.

>

>

> Comments may not be nested; it is an error if a left parenthesis is found after the start of a comment and before the end of the comment.

>

>

> Here is an example of a line containing a comment: `G80 M5 (stop motion)`

>

>

>

Source: [cnczone.com](https://www.cnczone.com/forums/g-code-programing/103434-coments-g-code.html#post763510) |

6,451 | <p>I am using a Flashforge Creator Dual Extrusion 3D Printer with RepG (<a href="http://replicat.org/" rel="nofollow noreferrer">ReplicatorG</a>), and tonight a print completely detached from the build plate.</p>

<p>I reset everything and watched it closely. It is a simple abs print at 230/110 degrees.</p>

<p>A few seconds after start of print, I noticed that the print bed temp had dropped to 109... and kept dropping.</p>

<p>This is new behavior. I haven't started to troubleshoot yet. I am looking for suggestions on how to troubleshoot the issue.</p>

<p><strong>Edit 1:</strong></p>

<p>Tonight RepG would not connect to the printer. I reseated the USB cord

and now it does.</p>

<p>The test print is ABS at 230/110 from this open scad.</p>

<pre><code>difference()

{

cylinder(d = 10, h = 2);

cylinder(d = 9, h = 2);

}

</code></pre>

<p>Pᴀᴜʟsᴛᴇʀ2/Oscar

Once the print starts the print bed begins cooling. It is cooling before

any filament is laid down.</p>

<p><strong>Edit 2:</strong></p>

<p>Examination of the gcode shows the root cause. It does contain</p>

<pre><code>M104 S230 T1 (set extruder temperature)

</code></pre>

<p>It does not contain a </p>

<pre><code>M109 S110 (set build plate temperature)

</code></pre>

<p>When I manually add the M109 to the gcode file, the model prints normally, and the build plate temperature holds for the duration of the print. </p>

<p>The drop in temperature last week is due to the fact that I tend to preheat the printer before actually starting the print. Since there was no M109 the bed plate cooled to ambient temperature.</p>

<p>There isn't a hardware issue here. Most likely it is a Rep G configuration error of some sort.</p>

<p><strong>Edit 3:</strong></p>

<p>I resolved the issue by a fresh install of the latest Rep G. I rebuilt the profiles from scratch with G Code to set the correct bed temp. Thank you for your suggestions.</p>

| [

{

"answer_id": 6453,

"author": "tbm0115",

"author_id": 98,

"author_profile": "https://3dprinting.stackexchange.com/users/98",

"pm_score": 2,

"selected": false,

"text": "<p>Your bed is obviously capable of heating up, so I would double check your cable for any kinks, cuts, blow-outs, or general connection issues both where your machine rests during warm-up and Z0 where your machine begins printing.</p>\n\n<p>Most likely there is a poor connector or kinked/cut wire for the build plate.</p>\n\n<p>If that doesn't appear to be the issue, I might also suggest checking your power supply. I've heard of other similar machines' power supplies not being quite strong enough to support two extruders AND a heated bed.</p>\n"

},

{

"answer_id": 6464,

"author": "cmm",

"author_id": 2082,

"author_profile": "https://3dprinting.stackexchange.com/users/2082",

"pm_score": 4,

"selected": true,

"text": "<p>Check your slicer settings. Some slicers allow the temperature to change at a specified layer. You may have programmed the slic3r to turn off the bed after the first (or maybe zeroth) layer.</p>\n\n<p>You call also examine the G-code for M140, M144, and M190 commands.</p>\n\n<p>Of course, the usual intermittent electric connections, power supply failures, etc. should be checked, but don't overlook the possibility that it is working exactly as you are asking it to work. </p>\n"

},

{

"answer_id": 6505,

"author": "0scar",

"author_id": 5740,

"author_profile": "https://3dprinting.stackexchange.com/users/5740",

"pm_score": 1,

"selected": false,

"text": "<p>Preheating the bed is a commonly used approach to shorten the time to print. I'll explain; it actually does not shorten the physical print time itself, but before you start a print there is always stuff to do like inserting the SD-card or loading the model in the print server, while you do that, the bed will be heating, so time gained.</p>\n\n<p>When you load a model it apparently resets the temperatures, so preheating will only have an effect when you also actually set the bed temperature in the G-code file. This means that either your G-code file has some codes that influence the temperature, the connector is loose or loading a print over the program you use must reset the bed temperature, there aren't any other options.</p>\n\n<p>To comment on your G-code, M109 is used to set the extruder temperature and wait till it is reached, M190 is used to set the bed temperature and wait till it is reached. Usually M190 is used to set the bed temperature before the first layer is being printed; the printer waits until the temperature is reached before the printer continues to the next command (usually the heating of the hotend). If you have selected a different temperature for the rest of the print you will find the M140 G-code command prior to printing the second layer.</p>\n\n<p>I have tested on my Prusa i3 clone running a Marlin fork to print a model with all references to M190 and M140 removed. I pre-heated to 70 °C (for PETG) and loaded the model in OctoPrint print server and commenced the print. The printer retained the bed value and did not drop.</p>\n\n<p>Basically, it is needed to take a closer look at your G-code file. The answer must be in there. If there is nothing to find in the G-code file and electronic connections are fine, the answer must be found in ReplicatorG, this might send reset signals prior to sending the print, but that sounds really strange.</p>\n"

}

] | 2018/07/23 | [

"https://3dprinting.stackexchange.com/questions/6451",

"https://3dprinting.stackexchange.com",

"https://3dprinting.stackexchange.com/users/1397/"

] | I am using a Flashforge Creator Dual Extrusion 3D Printer with RepG ([ReplicatorG](http://replicat.org/)), and tonight a print completely detached from the build plate.

I reset everything and watched it closely. It is a simple abs print at 230/110 degrees.

A few seconds after start of print, I noticed that the print bed temp had dropped to 109... and kept dropping.

This is new behavior. I haven't started to troubleshoot yet. I am looking for suggestions on how to troubleshoot the issue.

**Edit 1:**

Tonight RepG would not connect to the printer. I reseated the USB cord

and now it does.

The test print is ABS at 230/110 from this open scad.

```

difference()

{

cylinder(d = 10, h = 2);

cylinder(d = 9, h = 2);

}

```

Pᴀᴜʟsᴛᴇʀ2/Oscar

Once the print starts the print bed begins cooling. It is cooling before

any filament is laid down.

**Edit 2:**

Examination of the gcode shows the root cause. It does contain

```

M104 S230 T1 (set extruder temperature)

```

It does not contain a

```

M109 S110 (set build plate temperature)

```

When I manually add the M109 to the gcode file, the model prints normally, and the build plate temperature holds for the duration of the print.

The drop in temperature last week is due to the fact that I tend to preheat the printer before actually starting the print. Since there was no M109 the bed plate cooled to ambient temperature.

There isn't a hardware issue here. Most likely it is a Rep G configuration error of some sort.

**Edit 3:**

I resolved the issue by a fresh install of the latest Rep G. I rebuilt the profiles from scratch with G Code to set the correct bed temp. Thank you for your suggestions. | Check your slicer settings. Some slicers allow the temperature to change at a specified layer. You may have programmed the slic3r to turn off the bed after the first (or maybe zeroth) layer.

You call also examine the G-code for M140, M144, and M190 commands.

Of course, the usual intermittent electric connections, power supply failures, etc. should be checked, but don't overlook the possibility that it is working exactly as you are asking it to work. |

6,495 | <p>I had a Z probe installed but the wires came out of the header so I am trying to use software endstops, but any time I <code>G28</code> the nozzle will always ram into the bed. I am using Marlin Firmware. Which I am relatively new with. I'm used to having hardware endstops, but,</p>

<p><strong>I don't have a hardware endstop currently (no probe/no switch).</strong> </p>

<ul>

<li><p>Is it possible to do this with software? </p></li>

<li><p>I took out <code>G28</code>/<code>G29</code> in my G-code and it shows that it is going to z0.2 and working upward (but it still hits the bed). If the bed is level do I need a <code>G28</code>?</p></li>

<li><p>Should Z probe offset be 0?</p></li>

</ul>

<pre>

#define USE_XMIN_PLUG

#define USE_YMIN_PLUG

#define USE_ZMIN_PLUG

//#define USE_XMAX_PLUG

//#define USE_YMAX_PLUG

//#define USE_ZMAX_PLUG

#if DISABLED(ENDSTOPPULLUPS)

// fine endstop settings: Individual pullups. will be ignored if ENDSTOPPULLUPS is defined

//#define ENDSTOPPULLUP_XMAX

//#define ENDSTOPPULLUP_YMAX

//#define ENDSTOPPULLUP_ZMAX

//#define ENDSTOPPULLUP_XMIN

//#define ENDSTOPPULLUP_YMIN

//#define ENDSTOPPULLUP_ZMIN

//#define ENDSTOPPULLUP_ZMIN_PROBE

#endif

#define X_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Y_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Z_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define X_MAX_ENDSTOP_INVERTING false // set to true to invert the logic of the endstop.

#define Y_MAX_ENDSTOP_INVERTING false // set to true to invert the logic of the endstop.

#define Z_MAX_ENDSTOP_INVERTING false // set to true to invert the logic of the endstop.

#define Z_MIN_PROBE_ENDSTOP_INVERTING true // set to true to invert the logic of the probe.

// Enable this feature if all enabled endstop pins are interrupt-capable.

// This will remove the need to poll the interrupt pins, saving many CPU cycles.

#define ENDSTOP_INTERRUPTS_FEATURE

#define PROBE_MANUALLY

#define X_PROBE_OFFSET_FROM_EXTRUDER 1 // X offset: -left +right [of the nozzle]

#define Y_PROBE_OFFSET_FROM_EXTRUDER -55 // Y offset: -front +behind [the nozzle]

#define Z_PROBE_OFFSET_FROM_EXTRUDER -3.4

#define MULTIPLE_PROBING 2

#define Z_CLEARANCE_DEPLOY_PROBE 0 // Z Clearance for Deploy/Stow

#define Z_CLEARANCE_BETWEEN_PROBES 3 // Z Clearance between probe points

// For M851 give a range for adjusting the Z probe offset

#define Z_PROBE_OFFSET_RANGE_MIN -20

#define Z_PROBE_OFFSET_RANGE_MAX 20

#define INVERT_Z_DIR true

#define Z_MIN_POS 0

#if ENABLED(MIN_SOFTWARE_ENDSTOPS)

//#define MIN_SOFTWARE_ENDSTOP_X

//#define MIN_SOFTWARE_ENDSTOP_Y

#define MIN_SOFTWARE_ENDSTOP_Z

#endif

#define AUTO_BED_LEVELING_BILINEAR

#define MANUAL_Z_HOME_POS 0

#define Z_SAFE_HOMING

#if ENABLED(Z_SAFE_HOMING)

#define Z_SAFE_HOMING_X_POINT ((X_BED_SIZE) / 2) // X point for Z homing when homing all axes (G28).

#define Z_SAFE_HOMING_Y_POINT ((Y_BED_SIZE) / 2) // Y point for Z homing when homing all axes (G28).

#endif

</pre>

| [

{

"answer_id": 6491,

"author": "0scar",

"author_id": 5740,

"author_profile": "https://3dprinting.stackexchange.com/users/5740",

"pm_score": 2,

"selected": false,

"text": "<p>If you want to mirror the print to get the top to the bottom, and visa versa, you just need to rotate the part using the XYZ rotation tool. Mirroring is used to make a mirror image in the X-Z or Y-Z plane, not the X-Y plane. </p>\n\n<p>You might just caught a bug, you could post that of their forum.</p>\n\n<p>Update: </p>\n\n<p>If that does not fix it, you might have an incorrect STL model, e.g. the normals of the faces are incorrect. You could try to fix this by repairing the model through an online service like <a href=\"https://service.netfabb.com\" rel=\"nofollow noreferrer\">this one</a>.</p>\n"

},

{

"answer_id": 6492,

"author": "OyaMist",

"author_id": 10938,

"author_profile": "https://3dprinting.stackexchange.com/users/10938",

"pm_score": 2,

"selected": false,

"text": "<p>The up- or down-ness of a part is its Z-orientation, which is specified in STL. It looks like whoever published that STL file published it upside down, requiring you to flip the part or rotate it by 180. You can flip it in Cura as you've done or leave a comment to the author of the STL that the part is upside down. However, the author may not know how to fix this because low-end modeling tools typically do not have the capability of flipping a model. In these cases, using another tool such as Cura or Slicer can generate a right-side up model. Cura seems to like generating AMF files, so I use Slicer to generate STL files for upside down models. Once you correct the STL file, you'll be able to import the model directly into Cura right-side up.</p>\n"

}

] | 2018/07/29 | [

"https://3dprinting.stackexchange.com/questions/6495",

"https://3dprinting.stackexchange.com",

"https://3dprinting.stackexchange.com/users/12468/"

] | I had a Z probe installed but the wires came out of the header so I am trying to use software endstops, but any time I `G28` the nozzle will always ram into the bed. I am using Marlin Firmware. Which I am relatively new with. I'm used to having hardware endstops, but,

**I don't have a hardware endstop currently (no probe/no switch).**

* Is it possible to do this with software?

* I took out `G28`/`G29` in my G-code and it shows that it is going to z0.2 and working upward (but it still hits the bed). If the bed is level do I need a `G28`?

* Should Z probe offset be 0?

```

#define USE_XMIN_PLUG

#define USE_YMIN_PLUG

#define USE_ZMIN_PLUG

//#define USE_XMAX_PLUG

//#define USE_YMAX_PLUG

//#define USE_ZMAX_PLUG

#if DISABLED(ENDSTOPPULLUPS)

// fine endstop settings: Individual pullups. will be ignored if ENDSTOPPULLUPS is defined

//#define ENDSTOPPULLUP_XMAX

//#define ENDSTOPPULLUP_YMAX

//#define ENDSTOPPULLUP_ZMAX

//#define ENDSTOPPULLUP_XMIN

//#define ENDSTOPPULLUP_YMIN

//#define ENDSTOPPULLUP_ZMIN

//#define ENDSTOPPULLUP_ZMIN_PROBE

#endif

#define X_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Y_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Z_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define X_MAX_ENDSTOP_INVERTING false // set to true to invert the logic of the endstop.

#define Y_MAX_ENDSTOP_INVERTING false // set to true to invert the logic of the endstop.

#define Z_MAX_ENDSTOP_INVERTING false // set to true to invert the logic of the endstop.

#define Z_MIN_PROBE_ENDSTOP_INVERTING true // set to true to invert the logic of the probe.

// Enable this feature if all enabled endstop pins are interrupt-capable.

// This will remove the need to poll the interrupt pins, saving many CPU cycles.

#define ENDSTOP_INTERRUPTS_FEATURE

#define PROBE_MANUALLY

#define X_PROBE_OFFSET_FROM_EXTRUDER 1 // X offset: -left +right [of the nozzle]

#define Y_PROBE_OFFSET_FROM_EXTRUDER -55 // Y offset: -front +behind [the nozzle]

#define Z_PROBE_OFFSET_FROM_EXTRUDER -3.4

#define MULTIPLE_PROBING 2

#define Z_CLEARANCE_DEPLOY_PROBE 0 // Z Clearance for Deploy/Stow

#define Z_CLEARANCE_BETWEEN_PROBES 3 // Z Clearance between probe points

// For M851 give a range for adjusting the Z probe offset

#define Z_PROBE_OFFSET_RANGE_MIN -20

#define Z_PROBE_OFFSET_RANGE_MAX 20

#define INVERT_Z_DIR true

#define Z_MIN_POS 0

#if ENABLED(MIN_SOFTWARE_ENDSTOPS)

//#define MIN_SOFTWARE_ENDSTOP_X

//#define MIN_SOFTWARE_ENDSTOP_Y

#define MIN_SOFTWARE_ENDSTOP_Z

#endif

#define AUTO_BED_LEVELING_BILINEAR

#define MANUAL_Z_HOME_POS 0

#define Z_SAFE_HOMING

#if ENABLED(Z_SAFE_HOMING)

#define Z_SAFE_HOMING_X_POINT ((X_BED_SIZE) / 2) // X point for Z homing when homing all axes (G28).

#define Z_SAFE_HOMING_Y_POINT ((Y_BED_SIZE) / 2) // Y point for Z homing when homing all axes (G28).

#endif

``` | If you want to mirror the print to get the top to the bottom, and visa versa, you just need to rotate the part using the XYZ rotation tool. Mirroring is used to make a mirror image in the X-Z or Y-Z plane, not the X-Y plane.

You might just caught a bug, you could post that of their forum.

Update:

If that does not fix it, you might have an incorrect STL model, e.g. the normals of the faces are incorrect. You could try to fix this by repairing the model through an online service like [this one](https://service.netfabb.com). |

6,600 | <p>I have a printer with a 0.1 mm typical layer thickness. Of course I can choose some different sizes in Cura or other slicing software, but most prints on this machine will be .1mm. In my (admittedly limited) experience thus far, the 0.1 mm seems typical for other printers, too.</p>

<p>I want to get a sense of just how thick this is. I know about the paper trick for leveling the print bed, but my understanding is the first layer pushes into the bed a little, meaning it's less than 0.1 mm and so paper isn't a good example for the typical layer. </p>

<p>Is there a similar item with close to 0.1 mm thickness I can use to visualize this?</p>

| [

{

"answer_id": 6601,

"author": "Davo",

"author_id": 4922,

"author_profile": "https://3dprinting.stackexchange.com/users/4922",

"pm_score": 1,

"selected": false,

"text": "<p>Sure. Get a 0.1mm thick feeler gauge. </p>\n\n<p><a href=\"http://duckduckgo.com/?q=feeler+gauge+.1mm\" rel=\"nofollow noreferrer\">http://duckduckgo.com/?q=feeler+gauge+.1mm</a></p>\n"

},

{

"answer_id": 6604,

"author": "Greenonline",

"author_id": 4762,

"author_profile": "https://3dprinting.stackexchange.com/users/4762",

"pm_score": 3,

"selected": false,

"text": "<p>I'm not sure exactly what you mean by your comment to Davo's answer, but with respect to your use of a sheet of paper reference, it seems like you can still use <em>80 gsm</em> paper as a reference for 0.1 mm layers.</p>\n\n<p>From <a href=\"http://www.printware.co.uk/Blog/311/Paper-Sizes-Explained.html\" rel=\"nofollow noreferrer\">Paper Sizes Explained</a> (emphasis is mine):</p>\n\n<blockquote>\n <p>There is no universal calculation for the thickness of paper based on the gsm as varitaions in paper composition can affect the weight, so two different brands of 120gsm paper could have slightly different thicknesses. However, <strong>an average sheet of 80gsm paper, the most commonly used weight, measures approximately 0.1mm in thickness</strong>, which means that <em>10 sheets would measure 1mm</em>. By comparison, <em>10 sheets of 120gsm paper would be 1.5mm thick</em>, assuming the paper composition was the same.</p>\n</blockquote>\n\n<p>So, given that:</p>\n\n<ul>\n<li>80 gsm => 0.1 mm</li>\n<li>120 gsm => 0.15 mm</li>\n</ul>\n\n<p>Then </p>\n\n<ul>\n<li>40 gsm => 0.05 mm</li>\n<li>60 gsm => 0.075 mm</li>\n</ul>\n\n<p>From <a href=\"http://www.officexpress.co.uk/paper-guide/\" rel=\"nofollow noreferrer\">A Guide to Paper Types and Sizes</a></p>\n\n<pre><code>Paper Weight Descriptions\n\nWeight Feels Similar to:\n\n35-55 gsm Most newspapers\n90 gsm Mid-market magazine inner pages\n130-250 gsm A good quality promotional poster\n180-250 gsm Mid-market magazine cover\n350 gsm Most reasonable quality business cards\n</code></pre>\n\n<p>So, it would appear that you could use a newspaper sheet (or two) to test for layers of less than 0.1 mm. Obviously this would depend upon where in the world you are, and the (physical) quality of your newspapers. Here in the UK, or rather Europe, the <em>exported version</em> of the Guardian used to be printed on some extremely lightweight paper (almost transparent tissue thin), in order to keep the costs of transport down to a minimum. So a folded sheet of that would certainly be in the range of 0.75 - 0.99 mm (which seems to be the range that you are looking for). However, given that the printed media (as opposed to the online version) is currently in decline, I am not entirely sure if it is still available.</p>\n\n<p>Or, how about grease proof paper? From the <a href=\"https://en.wikipedia.org/wiki/Greaseproof_paper\" rel=\"nofollow noreferrer\">Wikipedia entry</a>:</p>\n\n<blockquote>\n <p>Basis weights are usually 30–50 g/m²</p>\n</blockquote>\n\n<p>Although, this paper has been processed (<a href=\"https://en.wikipedia.org/wiki/Supercalendered\" rel=\"nofollow noreferrer\">supercalandered</a>) and treated with starch, which will increase the density, so the thickness will not correlate to the table above (i.e. it will be thinner).</p>\n\n<p>Giftwrap paper (not the really thick stuff) could be another option.</p>\n\n<p>After having doing some long winded googling, I guess that the best bet would be to get hold of a micrometer and measure whatever paper yourself, as the specifications of paper are generally given in <code>gsm</code> and not <code>mm</code> (which is a bit annoying), and so it is somewhat difficult to provide you with a definitive answer (without physically measuring it).</p>\n"

},

{

"answer_id": 6617,

"author": "Sean Houlihane",

"author_id": 4927,

"author_profile": "https://3dprinting.stackexchange.com/users/4927",

"pm_score": 2,

"selected": false,

"text": "<p>Maybe a better way to visualise 0.1mm is to explain that it only becomes really visible on a shallow slope. A 10 degree slope will place one layer boundary every 8mm, and these steps will probably be visible on a print.</p>\n\n<p>For a sphere, such as the 3D-hubs marvin, this means that the top portion will have a clear layering, but the majority of the shape should have minimal visible layers. For example, this was printed at 0.1mm layer as a test:\n<a href=\"https://i.stack.imgur.com/Wxrcr.jpg\" rel=\"nofollow noreferrer\"><img src=\"https://i.stack.imgur.com/Wxrcr.jpg\" alt=\"Sean's Marvin\"></a>\nYou could also say that the layer is about the same as the embossing on a typical coin (using the same photo as a reference), but realise that the resolution of embossing is greater.</p>\n\n<p>Looking inside the eyes of this model demonstrates how a gentle slope exposes the presence of layers.</p>\n"

},

{

"answer_id": 7894,

"author": "Dmitry Kasatsky",

"author_id": 14121,

"author_profile": "https://3dprinting.stackexchange.com/users/14121",

"pm_score": 0,

"selected": false,

"text": "<p>IMO, better way for the thickness visualization is the <a href=\"https://en.wikipedia.org/wiki/Feeler_gauge\" rel=\"nofollow noreferrer\">feeler gauge</a>. Also it can be successfully used for the calibration of gap between the nozzle and the hotbed (instead paper)</p>\n"

}

] | 2018/08/08 | [

"https://3dprinting.stackexchange.com/questions/6600",

"https://3dprinting.stackexchange.com",

"https://3dprinting.stackexchange.com/users/12562/"

] | I have a printer with a 0.1 mm typical layer thickness. Of course I can choose some different sizes in Cura or other slicing software, but most prints on this machine will be .1mm. In my (admittedly limited) experience thus far, the 0.1 mm seems typical for other printers, too.

I want to get a sense of just how thick this is. I know about the paper trick for leveling the print bed, but my understanding is the first layer pushes into the bed a little, meaning it's less than 0.1 mm and so paper isn't a good example for the typical layer.

Is there a similar item with close to 0.1 mm thickness I can use to visualize this? | I'm not sure exactly what you mean by your comment to Davo's answer, but with respect to your use of a sheet of paper reference, it seems like you can still use *80 gsm* paper as a reference for 0.1 mm layers.

From [Paper Sizes Explained](http://www.printware.co.uk/Blog/311/Paper-Sizes-Explained.html) (emphasis is mine):

>

> There is no universal calculation for the thickness of paper based on the gsm as varitaions in paper composition can affect the weight, so two different brands of 120gsm paper could have slightly different thicknesses. However, **an average sheet of 80gsm paper, the most commonly used weight, measures approximately 0.1mm in thickness**, which means that *10 sheets would measure 1mm*. By comparison, *10 sheets of 120gsm paper would be 1.5mm thick*, assuming the paper composition was the same.

>

>

>

So, given that:

* 80 gsm => 0.1 mm

* 120 gsm => 0.15 mm

Then

* 40 gsm => 0.05 mm

* 60 gsm => 0.075 mm

From [A Guide to Paper Types and Sizes](http://www.officexpress.co.uk/paper-guide/)

```

Paper Weight Descriptions

Weight Feels Similar to:

35-55 gsm Most newspapers

90 gsm Mid-market magazine inner pages

130-250 gsm A good quality promotional poster

180-250 gsm Mid-market magazine cover

350 gsm Most reasonable quality business cards

```

So, it would appear that you could use a newspaper sheet (or two) to test for layers of less than 0.1 mm. Obviously this would depend upon where in the world you are, and the (physical) quality of your newspapers. Here in the UK, or rather Europe, the *exported version* of the Guardian used to be printed on some extremely lightweight paper (almost transparent tissue thin), in order to keep the costs of transport down to a minimum. So a folded sheet of that would certainly be in the range of 0.75 - 0.99 mm (which seems to be the range that you are looking for). However, given that the printed media (as opposed to the online version) is currently in decline, I am not entirely sure if it is still available.

Or, how about grease proof paper? From the [Wikipedia entry](https://en.wikipedia.org/wiki/Greaseproof_paper):

>

> Basis weights are usually 30–50 g/m²

>

>

>

Although, this paper has been processed ([supercalandered](https://en.wikipedia.org/wiki/Supercalendered)) and treated with starch, which will increase the density, so the thickness will not correlate to the table above (i.e. it will be thinner).

Giftwrap paper (not the really thick stuff) could be another option.

After having doing some long winded googling, I guess that the best bet would be to get hold of a micrometer and measure whatever paper yourself, as the specifications of paper are generally given in `gsm` and not `mm` (which is a bit annoying), and so it is somewhat difficult to provide you with a definitive answer (without physically measuring it). |

6,606 | <p>I've just bought <strong>Anycubic i3 Mega</strong> printer and trying to level it.

So far I've printed test object and 2 others but looks like there are problems with leveling.</p>

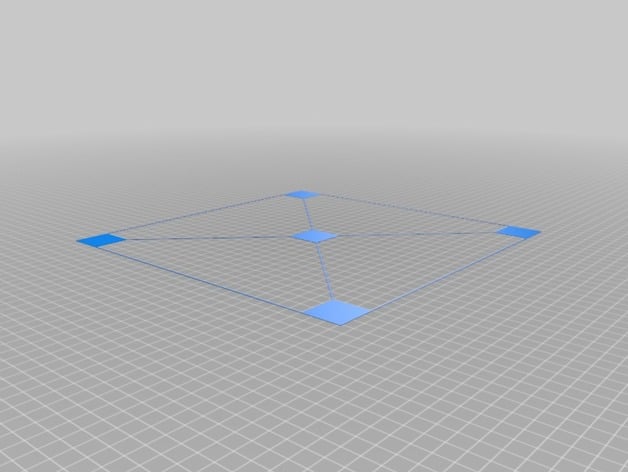

<p>I want to make image of 5 small one layer squares(one in each corner and one in center). Looking for recommendations of <strong>simple</strong> software/tutorials/approaches to do it. I tried zbrush but found that it kind of complicated.</p>

| [

{

"answer_id": 6609,

"author": "0scar",

"author_id": 5740,

"author_profile": "https://3dprinting.stackexchange.com/users/5740",

"pm_score": 4,

"selected": true,

"text": "<p>You are probably looking for something like <a href=\"https://www.thingiverse.com/thing:2479352\" rel=\"nofollow noreferrer\">this</a>:</p>\n\n<p><img src=\"https://cdn.thingiverse.com/renders/0f/68/62/46/9f/646e9a4ee9ff75a7f0cacb396a0b7ed4_preview_featured.jpg\" alt=\"leveling print object\"></p>\n\n<p>Note this is for large beds (300 x 300 mm), so you would have to X, Y scale this in your slicer.</p>\n\n<p>This is a simple part that is very easily generated with <a href=\"http://www.openscad.org\" rel=\"nofollow noreferrer\">OpenSCAD</a> 3D design software (very good modeller if you are familiar with software coding), but could easily been designed in any <a href=\"https://en.m.wikipedia.org/wiki/List_of_3D_modeling_software\" rel=\"nofollow noreferrer\">other tool</a>.</p>\n\n<p>Another leveling and centering print that is created with OpenSCAD is <a href=\"https://www.thingiverse.com/thing:2280529\" rel=\"nofollow noreferrer\">this</a>, and could be a start for you to create your own design:</p>\n\n<p><a href=\"https://i.stack.imgur.com/mH73a.jpg\" rel=\"nofollow noreferrer\"><img src=\"https://i.stack.imgur.com/mH73a.jpg\" alt=\"leveling and centering print object\"></a></p>\n\n<p>Note that the file with the design is located in the \"files\" section.</p>\n\n<p><strong>Edit</strong>:\nSome code for OpenSCAD made within 5 minutes (I don't type fast so it could have been faster if I did not use the constants, but if you go OpenSCAD, making parametric designs is almost a must ;) ):</p>\n\n<pre><code>// Set constants as you like\nwidth = 30;\ndepth = 30;\nlayer_height = 0.2;\nfirst_layer_height = 0.2;\nnr_of_layers = 2;\nbox_size = 180;\n\n// Calculated parameters\nheight = first_layer_height + (nr_of_layers - 1) * layer_height;\n\n// Draw the test object\ntranslate([-width/2, -depth/2,0]){\n // Draw the center square\n cube(size = [width, depth, height], center = false);\n // Draw the corner squares\n for (x=[-1:2:1]){\n for (y=[-1:2:1]){\n translate([x * (box_size-width)/2, y * (box_size-depth)/2, 0])\n cube(size = [width, depth, height], center = false);\n } \n } \n}\n</code></pre>\n\n<p>Rendered figure:\n<a href=\"https://i.stack.imgur.com/bVNru.png\" rel=\"nofollow noreferrer\"><img src=\"https://i.stack.imgur.com/bVNru.png\" alt=\"rendered image of the 5 square level test print\"></a></p>\n"

},

{

"answer_id": 6611,

"author": "Sean Houlihane",

"author_id": 4927,

"author_profile": "https://3dprinting.stackexchange.com/users/4927",

"pm_score": 2,

"selected": false,

"text": "<p>One of the most accessible modelling tools has to be <a href=\"https://www.tinkercad.com/\" rel=\"nofollow noreferrer\">tinkercad</a>. Everything is done in the browser, and it even works (to an extent) on a tablet. </p>\n\n<p>I wouldn't recommend getting too attached to it, since it is fairly limited. As an introduction to modeling in 3D, and some of the spatial concepts that you will need to get used to, it works very well.</p>\n"

}

] | 2018/08/08 | [

"https://3dprinting.stackexchange.com/questions/6606",

"https://3dprinting.stackexchange.com",

"https://3dprinting.stackexchange.com/users/12587/"

] | I've just bought **Anycubic i3 Mega** printer and trying to level it.

So far I've printed test object and 2 others but looks like there are problems with leveling.

I want to make image of 5 small one layer squares(one in each corner and one in center). Looking for recommendations of **simple** software/tutorials/approaches to do it. I tried zbrush but found that it kind of complicated. | You are probably looking for something like [this](https://www.thingiverse.com/thing:2479352):

Note this is for large beds (300 x 300 mm), so you would have to X, Y scale this in your slicer.

This is a simple part that is very easily generated with [OpenSCAD](http://www.openscad.org) 3D design software (very good modeller if you are familiar with software coding), but could easily been designed in any [other tool](https://en.m.wikipedia.org/wiki/List_of_3D_modeling_software).

Another leveling and centering print that is created with OpenSCAD is [this](https://www.thingiverse.com/thing:2280529), and could be a start for you to create your own design:

[](https://i.stack.imgur.com/mH73a.jpg)

Note that the file with the design is located in the "files" section.

**Edit**:

Some code for OpenSCAD made within 5 minutes (I don't type fast so it could have been faster if I did not use the constants, but if you go OpenSCAD, making parametric designs is almost a must ;) ):

```

// Set constants as you like

width = 30;

depth = 30;

layer_height = 0.2;

first_layer_height = 0.2;

nr_of_layers = 2;

box_size = 180;

// Calculated parameters

height = first_layer_height + (nr_of_layers - 1) * layer_height;

// Draw the test object

translate([-width/2, -depth/2,0]){

// Draw the center square

cube(size = [width, depth, height], center = false);

// Draw the corner squares

for (x=[-1:2:1]){

for (y=[-1:2:1]){

translate([x * (box_size-width)/2, y * (box_size-depth)/2, 0])

cube(size = [width, depth, height], center = false);

}

}

}

```

Rendered figure:

[](https://i.stack.imgur.com/bVNru.png) |

6,619 | <p>I think it's best that I explain what my issue is before I explain how I arrived here. I have a Tronxy x5s with a stock board that I am repairing for the sake of repairing, even though I know I should probably just spring for a new board. It's the principle of the thing. </p>

<ul>

<li>The extruder thermistor accurately reads for a few seconds, and then gives a negative reading as if it's been unplugged. </li>

<li>I know that this is the same reading of an unplugged thermistor because when you unplug either the extruder or bed thermistor from a known-good port, it gives this same negative reading. </li>

<li>It is not attached to the original pin. It is attached to a new pin that I moved it to. I cut the old pin off from the thermistor port and soldered the new pin to the traces of the port. Then I changed the pin in the configuration file, and it works, for a while.</li>

<li>The electronics are messy but sound; I have used my voltmeter to verify connectivity and voltage. </li>

<li>The thermistor works; it reads a little over 100kΩ in my hot garage and the temperature changes after I put it in my hand for a few minutes. But this temperature change only registers, as explained in the rest, for a few seconds. </li>

<li>I am sure there's a configuration somewhere in the firmware that I am missing that causes that pin to either go "off" or become disused after a few seconds. </li>

</ul>

<p>Greater context: </p>

<p>The printer was working great for months, but one day the extruder thermistor shorted so badly that the Analog to Digital pin on the Arduino powering the Melzi board was permanently damaged. The temperature reading consistently stayed at 260 °C, even when unplugged. </p>

<p>I wanted to come up with a repair solution rather than replacing the board (even though I have plans to do that anyway), so I downloaded the datasheet for the Arduino Mega 1248P and looked for other ADC pins I could use. I found that ADC Pin0 was unused on the board, so I thought I'd isolate old pin (ADC Pin 7), solder the trace to the new pin, and change the firmware to reflect the new pin. </p>

<p><a href="https://i.imgur.com/qMlxw9T.jpg" rel="noreferrer" title="Datasheet pinout"><img src="https://i.imgur.com/qMlxw9T.jpg" alt="Datasheet pinout" title="Datasheet pinout"></a></p>

<p><a href="https://i.imgur.com/D6M5Gq5.jpg" rel="noreferrer" title="Photo of trace and isolation"><img src="https://i.imgur.com/D6M5Gq5.jpg" alt="Photo of trace and isolation" title="Photo of trace and isolation"></a> </p>

<p>Then I changed the pin used for that extruder thermistor reading in the <code>Pins_SANGUINOLOLU_11.h</code> config file (the old Melzi board for the Tronxy X5s is a Sanguino): </p>

<pre><code>// Temperature Sensors

//

#define TEMP_0_PIN 7 // Analog Input (pin 33 extruder)

#define TEMP_BED_PIN 6 // Analog Input (pin 34 bed)

</code></pre>

<p>Changed to </p>

<pre><code>// Temperature Sensors

//

#define TEMP_0_PIN 0 // Analog Input (pin xx extruder)

#define TEMP_BED_PIN 6 // Analog Input (pin 34 bed)

</code></pre>

<p>I didn't know what "pin 33" was or used to be so I just put xx in the comment. </p>

<p>Anyway, my hardware was good, and my software was supposedly good, so I flashed the new firmware, plugged it in, and turned it on: </p>

<p><a href="https://i.imgur.com/xER2LQP.jpg" rel="noreferrer" title="Good temperature reading"><img src="https://i.imgur.com/xER2LQP.jpg" alt="Good temperature reading" title="Good temperature reading"></a></p>

<p>Yay! But after a few seconds... </p>

<p><a href="https://i.imgur.com/oa1qwwZ.jpg" rel="noreferrer" title="Bad temperature reading"><img src="https://i.imgur.com/oa1qwwZ.jpg" alt="Bad temperature reading" title="Bad temperature reading"></a></p>

<p>Boo. It stops working. </p>

<p>I am sure my connections are solid: I've tested for connectivity and voltage. Both the new port and the heat bed thermistor port get 4.97 volts, so it's not a voltage drop. It's something in the Arduino. </p>

<p>Any ideas? </p>

| [

{

"answer_id": 6701,

"author": "entropicCreator",

"author_id": 12706,

"author_profile": "https://3dprinting.stackexchange.com/users/12706",

"pm_score": 1,

"selected": false,

"text": "<p>Thermal expansion is opening a connection somewhere. It might not be one of your solderings, but if you shorted the board bad enough to fry pins, it could have cooked something somewhere else, and putting current through it is heating up the spot enough to break the connection. Either somewhere else in/on the board, or inside of the IC chip itself. </p>\n"

},

{

"answer_id": 15442,

"author": "Jpawlin",

"author_id": 26500,

"author_profile": "https://3dprinting.stackexchange.com/users/26500",

"pm_score": 0,

"selected": false,

"text": "<p>I am having the same issue so in the firmware instead of changing to an empty pin, I swapped pins 6 and 7 so the nozzle temp would read from the bed temp plug on the board. Now the nozzle temp is reading properly i went into configurations.h line 291 and changed the 1 to 999 and on line 295 i changed the value to 60 now the bed temp will always be 60 so as long as my print settings match it will never engage the heat bed and allow the machine to print. Now I will use an ESP8266 nodeMCU to read the temp and control the MOSFET for the heat bed.</p>\n"

}

] | 2018/08/09 | [

"https://3dprinting.stackexchange.com/questions/6619",

"https://3dprinting.stackexchange.com",

"https://3dprinting.stackexchange.com/users/12596/"

] | I think it's best that I explain what my issue is before I explain how I arrived here. I have a Tronxy x5s with a stock board that I am repairing for the sake of repairing, even though I know I should probably just spring for a new board. It's the principle of the thing.

* The extruder thermistor accurately reads for a few seconds, and then gives a negative reading as if it's been unplugged.

* I know that this is the same reading of an unplugged thermistor because when you unplug either the extruder or bed thermistor from a known-good port, it gives this same negative reading.

* It is not attached to the original pin. It is attached to a new pin that I moved it to. I cut the old pin off from the thermistor port and soldered the new pin to the traces of the port. Then I changed the pin in the configuration file, and it works, for a while.

* The electronics are messy but sound; I have used my voltmeter to verify connectivity and voltage.

* The thermistor works; it reads a little over 100kΩ in my hot garage and the temperature changes after I put it in my hand for a few minutes. But this temperature change only registers, as explained in the rest, for a few seconds.

* I am sure there's a configuration somewhere in the firmware that I am missing that causes that pin to either go "off" or become disused after a few seconds.

Greater context:

The printer was working great for months, but one day the extruder thermistor shorted so badly that the Analog to Digital pin on the Arduino powering the Melzi board was permanently damaged. The temperature reading consistently stayed at 260 °C, even when unplugged.

I wanted to come up with a repair solution rather than replacing the board (even though I have plans to do that anyway), so I downloaded the datasheet for the Arduino Mega 1248P and looked for other ADC pins I could use. I found that ADC Pin0 was unused on the board, so I thought I'd isolate old pin (ADC Pin 7), solder the trace to the new pin, and change the firmware to reflect the new pin.

[](https://i.imgur.com/qMlxw9T.jpg "Datasheet pinout")

[](https://i.imgur.com/D6M5Gq5.jpg "Photo of trace and isolation")

Then I changed the pin used for that extruder thermistor reading in the `Pins_SANGUINOLOLU_11.h` config file (the old Melzi board for the Tronxy X5s is a Sanguino):

```

// Temperature Sensors

//

#define TEMP_0_PIN 7 // Analog Input (pin 33 extruder)

#define TEMP_BED_PIN 6 // Analog Input (pin 34 bed)

```

Changed to

```

// Temperature Sensors

//

#define TEMP_0_PIN 0 // Analog Input (pin xx extruder)

#define TEMP_BED_PIN 6 // Analog Input (pin 34 bed)

```

I didn't know what "pin 33" was or used to be so I just put xx in the comment.

Anyway, my hardware was good, and my software was supposedly good, so I flashed the new firmware, plugged it in, and turned it on:

[](https://i.imgur.com/xER2LQP.jpg "Good temperature reading")

Yay! But after a few seconds...

[](https://i.imgur.com/oa1qwwZ.jpg "Bad temperature reading")

Boo. It stops working.

I am sure my connections are solid: I've tested for connectivity and voltage. Both the new port and the heat bed thermistor port get 4.97 volts, so it's not a voltage drop. It's something in the Arduino.

Any ideas? | Thermal expansion is opening a connection somewhere. It might not be one of your solderings, but if you shorted the board bad enough to fry pins, it could have cooked something somewhere else, and putting current through it is heating up the spot enough to break the connection. Either somewhere else in/on the board, or inside of the IC chip itself. |

6,744 | <p>ISSUE: Stepper motors are not working when connected with RAMPS 1.4.</p>

<p>OBSERVATION: The LED lights(LED 2,3,4) in the RAMPS 1.4 is not powering up.</p>

<p>PRACTICES: I use Arduino Mega 2560 and installed Marlin firmware in it. And I bought a RAMPS 1.4 in a local electronic dealer. I placed the RAMPS over Arduino Mega 2560. For testing I just connected 2 NEMA 17 stepper motors with RAMPS. When USB port connection is given from laptop to Arduino board, a LED light is ON in Arduino board (L) and in RAMPS (LED 1). I use SMPS 12 V 20 A as a PSU for RAMPS. But in RAMPS the LED 2, 3, 4 are not switched ON. I checked the input voltage to the RAMPS using micrometer and it shows 11.75 V. But there is no output from the RAMPS.</p>

<p>Also I installed and tried Repetier firmware and Grbl but it doesn't work. And I use Windows 10 pro 64 bit OS.</p>

<p>When I flashed Arduino with Grbl, in this case all of the LEDs on the Arduino and RAMPS 1.4 are switched ON. I use Candle GRBL software to test the stepper motors.</p>

<p>And I replaced and tested with another RAMPS which is bought from Amazon but the problem remains unchanged.</p>

<p>Kindly give some suggestions at the earliest.</p>

<p>I have attached the images of my circuit connection:</p>

<p><a href="https://i.imgur.com/k39rd7t.jpg" rel="nofollow noreferrer"><img src="https://i.imgur.com/k39rd7t.jpg" alt="i.imgur.com/k39rd7t.jpg"></a></p>

<p><a href="https://i.imgur.com/OPPuElQ.jpg" rel="nofollow noreferrer"><img src="https://i.imgur.com/OPPuElQ.jpg" alt="i.imgur.com/OPPuElQ.jpg"></a></p>

<p><a href="https://i.imgur.com/mM3BIEn.jpg" rel="nofollow noreferrer"><img src="https://i.imgur.com/mM3BIEn.jpg" alt="i.imgur.com/mM3BIEn.jpg"></a> </p>

<p>Board selection in Marlin:</p>

<pre><code>#ifndef MOTHERBOARD

#define MOTHERBOARD BOARD_RAMPS_14_EFB

#endif

</code></pre>

<h3>Additional clarifications</h3>

<p>In response to Professor's questions:</p>

<ol>

<li>Yes the stepper drivers are connected correctly </li>

<li>Yes the stepper wiring is accurate (2B 2A 1A 1B) as per mentioned in the Ramps 1.4. </li>

<li>No there is no voltage input to stepper motor. But there is 12V input to Ramps 1.4. </li>

<li>Disabled cold extrusion </li>

<li>No, the firmware is not set to no move before homing (issue G28 first) </li>

<li>Yes, pins are set correctly for your board in Marlin</li>

</ol>

| [

{

"answer_id": 6745,

"author": "profesor79",

"author_id": 9730,

"author_profile": "https://3dprinting.stackexchange.com/users/9730",

"pm_score": 1,

"selected": false,

"text": "<p>to help you to solve this problem - please see my checklist</p>\n\n<ol>\n<li>are the stepper drivers connected correctly (pin1 to pin1)?</li>\n<li>stepper wiring is accurate (1a-1a..2b-2b)?</li>\n<li>is there enough voltage provided to the steppers (regulate)?</li>\n<li>if you are trying to move E0 or E1 then you need to disable cold extrusion as that stops rotation (waiting for 170C deg on the nozzle)</li>\n<li>is the firmware set to no move before homing (issue G28 first)?</li>\n<li>are pins set correctly for your board in Marlin?</li>\n</ol>\n\n<p>the led's are set on my ramps as they are mostly giving a stutus for heater fan and bed, so grbl software could use those pins differently</p>\n"

},

{

"answer_id": 7175,

"author": "Baalaji V",

"author_id": 12765,

"author_profile": "https://3dprinting.stackexchange.com/users/12765",

"pm_score": 2,

"selected": false,

"text": "<p>I actually thought the problem is in the electronic circuit but the problem is the baud rate. I initially took the baud rate as 115200 but later. after someone's suggestion, I changed it to 250000 and now it's fine.</p>\n"

}

] | 2018/08/27 | [

"https://3dprinting.stackexchange.com/questions/6744",

"https://3dprinting.stackexchange.com",

"https://3dprinting.stackexchange.com/users/12765/"

] | ISSUE: Stepper motors are not working when connected with RAMPS 1.4.

OBSERVATION: The LED lights(LED 2,3,4) in the RAMPS 1.4 is not powering up.

PRACTICES: I use Arduino Mega 2560 and installed Marlin firmware in it. And I bought a RAMPS 1.4 in a local electronic dealer. I placed the RAMPS over Arduino Mega 2560. For testing I just connected 2 NEMA 17 stepper motors with RAMPS. When USB port connection is given from laptop to Arduino board, a LED light is ON in Arduino board (L) and in RAMPS (LED 1). I use SMPS 12 V 20 A as a PSU for RAMPS. But in RAMPS the LED 2, 3, 4 are not switched ON. I checked the input voltage to the RAMPS using micrometer and it shows 11.75 V. But there is no output from the RAMPS.

Also I installed and tried Repetier firmware and Grbl but it doesn't work. And I use Windows 10 pro 64 bit OS.

When I flashed Arduino with Grbl, in this case all of the LEDs on the Arduino and RAMPS 1.4 are switched ON. I use Candle GRBL software to test the stepper motors.

And I replaced and tested with another RAMPS which is bought from Amazon but the problem remains unchanged.

Kindly give some suggestions at the earliest.

I have attached the images of my circuit connection:

[](https://i.imgur.com/k39rd7t.jpg)

[](https://i.imgur.com/OPPuElQ.jpg)

[](https://i.imgur.com/mM3BIEn.jpg)

Board selection in Marlin:

```

#ifndef MOTHERBOARD

#define MOTHERBOARD BOARD_RAMPS_14_EFB

#endif

```

### Additional clarifications

In response to Professor's questions:

1. Yes the stepper drivers are connected correctly

2. Yes the stepper wiring is accurate (2B 2A 1A 1B) as per mentioned in the Ramps 1.4.

3. No there is no voltage input to stepper motor. But there is 12V input to Ramps 1.4.

4. Disabled cold extrusion

5. No, the firmware is not set to no move before homing (issue G28 first)

6. Yes, pins are set correctly for your board in Marlin | I actually thought the problem is in the electronic circuit but the problem is the baud rate. I initially took the baud rate as 115200 but later. after someone's suggestion, I changed it to 250000 and now it's fine. |